Intrigued by the advent of micromobility vehicles including electric scooters, bicycles and skateboards, during the summer of 2019 I designed my own direct-drive hub motor as a personal project. The 54 mm brushless hub motor I manufactured was meant to attach to a conventional skateboard truck axle. The hub motor houses a 3008 outrunner stator with 12 electromagnet poles, and for testing purposes the hub motor was 3D printed in PETG plastic. A soft outer rubber layer was 3D printed using TPU filament. I decided on using 14 N52 permanent magnets to form the rotor because a 12N, 14P (12 wire wound stator poles, 14 permanent magnet rotor poles) configuration allows for increased torque, a necessity, especially with a design that uses a small diameter rotor and stator. The stator was wound with 28 AWG magnet wire in a winding scheme terminated in a WYE configuration so as to draw less current. The motor leads are connected to an electronic speed controller (ESC) and are powered by a 4s lithium polymer battery. In tests the hub motor achieved high speeds but was lacking in torque due to its small stator and rotor diameters. Future improvements could include increasing the diameter of the hub motor to improve torque and machining the hub motor housing from aluminum to allow for load-bearing tests and better heat dissipation.

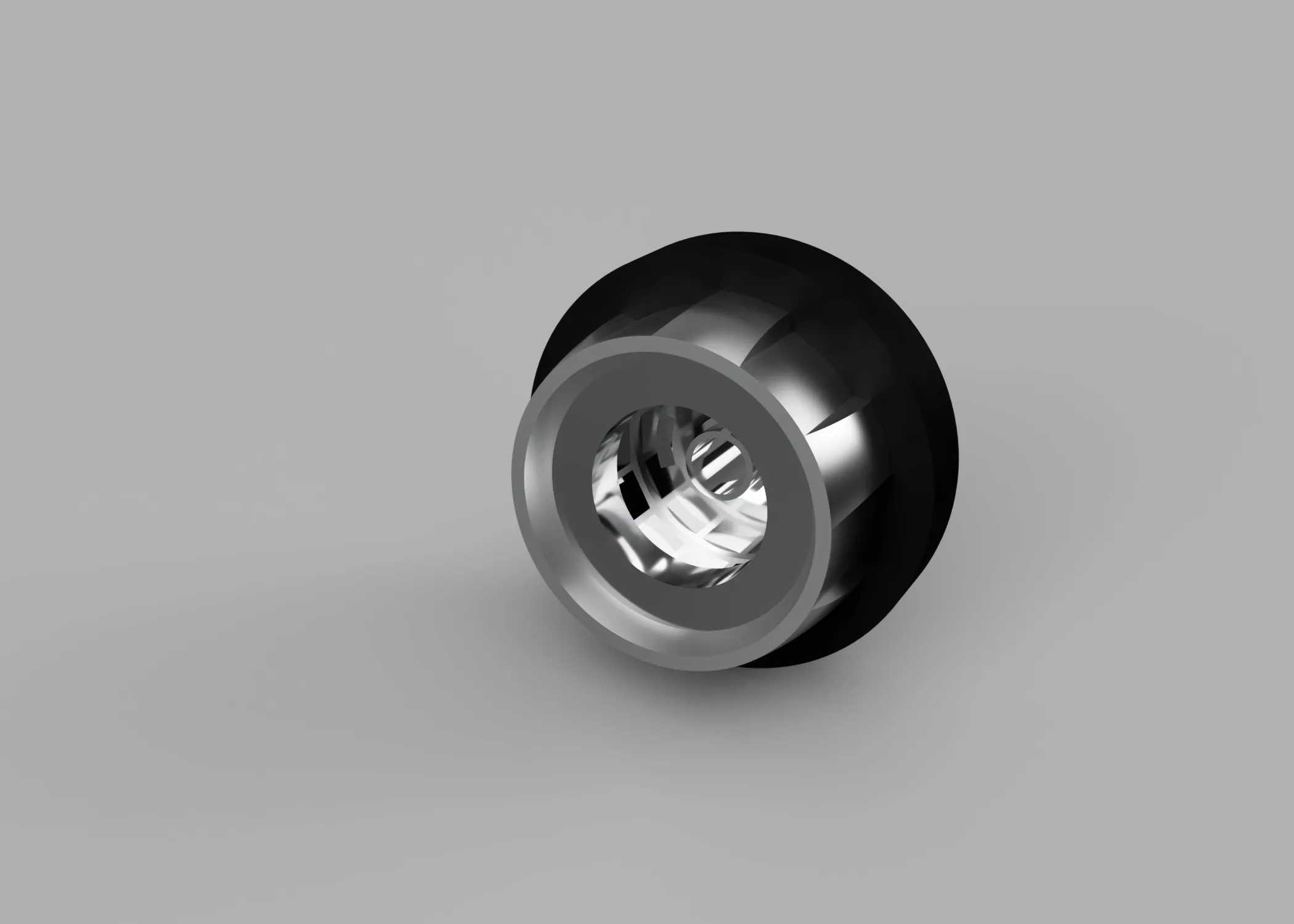

A cross sectional view of the brushless hub motor. The stator is positioned within the outer frame of the hub motor and 14 N52 permanent magnets are positioned around it. The rubber wheel is pressed over the hub motor out-runner and is held in place by 6 arced grooves.

A demonstration of the brushless hub motor in operation mounted to a skateboard truck axle.